You now know how to prepare your laboratory glassware before performing the machine treatment in order to avoid all risks related to possible residues.

The automaton programs are not sufficient enough to properly process laboratory glassware. This is why it is necessary to follow some recommendations such as the equipment positioning in the machine or the different treatment processes.

Machine processing

The glassware equipment with a wide opening needs to be placed at the level of the rotating spray arms :

- Beakers

- Petri dishes

- Grinding bowls

- Watchglasses

- Wide neck erlenmeyer flasks

- Wide neck laboratory vials

- Low graduated cylinders

- Test tubes (if light soiling)

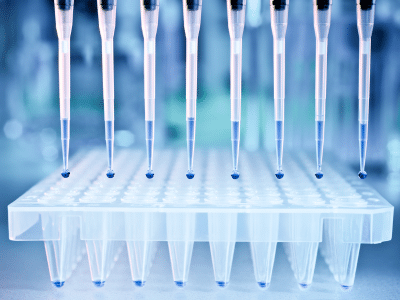

The laboratory glassware with a small opening needs to be positionned on the injection nozzles :

- Round bottom flasks

- Narrow neck erlenmeyer flasks

- Vials

- Volumetric vials

- High graduated cylinders

- Test tubes (if heavy soiling)

Be careful : A space between the nozzle and the bottom of the glassware is mandatory : no contact should be made. For the narrow neck vials, the nozzle must exceed the neck and place at the entrance of the domed part.

The long and thin glass utensils with a very small opening must be on injection sleeves :

- Pipettes

Be careful : It is necessary to position the pipette’s tip in the injection sleeves.

- Avoid the rinse dead areas

- Do not accumulate equipment

- Ballast light glassware

- Do not block spray arms

- Prevent tipping

- Avoid contact between utensils

- Do not protude the glassware from the loading supports

The Sinner’s Circle helps to understand which parameters make cleaning effective.

- Cleaning

- Neutralization

- Rinse

- Disinfection

- Drying

Process A :

- Prewash : cold water, without heating, without chemical treatment product

- Cleaning : hot/cold water, with heating, with alkaline cleaning products

- Neutralization : hot/cold water, without heating, with acide neutralizing agents

- Several rinses : hot/cold water or fully demineralised water / ultra pure water , without heating

- Subsequent rinse : fully demineralised water / ultra pure water, with heating

- Drying

Works published by Miele

Process B :

- Prewash : cold water, with heating, with acid cleaning products

- Cleaning : hot/cold water, with heating, with alkaline cleaning products

- Neutralization : hot/cold water, without heating, with acide neutralizing agents

- Several rinses : hot/cold water or fully demineralised water / ultra pure water , without heating

- Subsequent rinse : fully demineralised water / ultra pure water, with heating

- Drying

Works published by Miele

Process C :

- Prewash : hot/cold water, with heating, with alkaline cleaning products

- Cleaning : hot/cold water, with heating, with alkaline cleaning products

- Neutralization : hot/cold water, without heating, with acide neutralizing agents

- Several rinses : hot/cold water or fully demineralised water / ultra pure water , without heating

- Subsequent rinse : fully demineralised water / ultra pure water, with heating

- Drying

Works published by Miele

| Activity type | Impurity type | Process choice |

|---|---|---|

| General | General impurities, diluting relatively well in water | A |

| Marker inscription | A | |

| Résidus d’étiquette | A ou C | |

| Water and environment analyzes | Limestome residues and algae | B |

| Inorganic analyzes | B | |

| Organic analyzes | A ou C | |

| Microbiological analyzes | A | |

| Agar | C | |

| Nutrient mediums | A ou B | |

| Oil industry | Crude oil, mineral oils | C |

| Cosmetics industry | Cream, ointments | C |

| Food industry | Inorganic analyzes | B |

| Organic analyzes | A ou C | |

| Microbiological analyzes | A | |

| Biology, microbiology, biotechnology | Cell and tissue cultures, sterilized if applicable | A ou C |

| Agar | C | |

| Nutrient mediums | A ou B | |

| Organic residues, sterilized if applicable | A ou C | |

| Pathology | Paraffin wax | C |

| Hospital laboratory | Uncoagulated blood | A |

| Blood bank | Uncoagulated blood | A |

Works published by Miele

After preparing and processing your laboratory glassware, be aware that there are still other recommended procedures in regards of the control and the output of the automaton, the sterilization if applicable or the storage of clean glassware.